The EB29R the self-launching, high-performance single-seater for the Open Class

EB29R Single Seater

Maximum performance. Minimum drag. Pure Innovation – EB29R sets new standards in the Open Class for competitions as well as cross-country flights.

The newly developed wing profile (developed by Loek Boermanns) allows peak performance in the high-speed range and very good circling characteristics at high wing loading. High modulus fiber throughout the entire wing shell produces a very high stiffness, which is charactteristic in fast flight.

The EB29R combines uncompromising performance and innovative technology in a high-performance single-seater. High wing aspect ratio and low wing area ensure outstanding glide performance and excellent handling, even at maximum wing loadings.

Further technical highlights such as the electrically operated landing gear with long travel, the steerable and electrically retractable tailwheel, the precise trim on the control stick, and carbon fiber control rods enhance performance.

The retractable propulsion system with Solo Motor and proprietary propeller impresses with its power and reliability. Over 30 years of experience with retractable propulsion systems are integrated into its development.

Are you curious?

Get to know our aircraft and all their technical features in person – we will be happy to advise you!

Technical Data

| wingspan | 28 m |

| wing area | 14,9 m² |

| wing aspect ratio | 52,6 |

| fuselage length | 8,0 m |

| height (fin plus tailwheel) | 1,8 m |

| empty weight with minimal equipment | ca. 610 kg |

| maximum ramp weight | 850 kg |

| wing loading minimum | ca. 46,5 kg/m² |

| wing loading maximum | 57,5 kg/m² |

| maximum speed | 270 km/h |

| best glideerratio | ca. 66 |

| Solo engine | ca. 63 PS |

| composite propeller Binder BM-G1 | d 1,6 m |

| rate of climb with engine | 2,6 m/s |

| cruise speed in powered flight | max.160 km/h |

| fuel capacity (standard) | 23 ltr |

| data sheet | EASA.A.559 |

description

fuselage

- body shell made off reinforced plastic (CFK and aramide)

- extra spacious cockpit suitable also for tall pilots

- forward swinging canopy including one sliding window with integrated ventilation scoop

- instrument panel moves upward with the canopy

- TOST-safety release (for aero tow)

- total pressure probe in tip of the fuselage nose

- coneadapter in the fin to fit TEK

- probestatic pressure probes (for air speed indicator and altimeter) on both sides of the tail boom

landing gear and brake

- rubber suspended, electrically operated retractable landing gear

- hydraulic disk brake

- tailwheel (optional steerable and electrically retractable)

power plant

- power plant retractable into the fuselage

- solo engine 2625 02

- tooth belt driven reduction gear (1:3)

- water cooling

- double ignition

- electrical starter

- batteries with 16,8 V max charching voltage for improved extension and retraction as well as starting of the engine

- engine control instrument fitted to the instrument panel

- Propeller Binder BM-G1-160-R-120-1

fuel tank

- fuselage tank ~23 ltr

- optional auxiliary tank ~5 ltr

antenna

- radio antenna in rudder

- optional transponder antenna in rudder

cockpit

- removeable bucket seat

- safety belt

- seat cushion

- ram air entrance in the nosecone of the fuselage for ventilation and defogging of the canopy

- controllable ventilation on right side of the cockpit

controls

- rudder control pedals adjustable during flight

- control rods made of CFK

- electrically adjustable trim with the operating switch on the control stick

- automatic elevator connection

wing

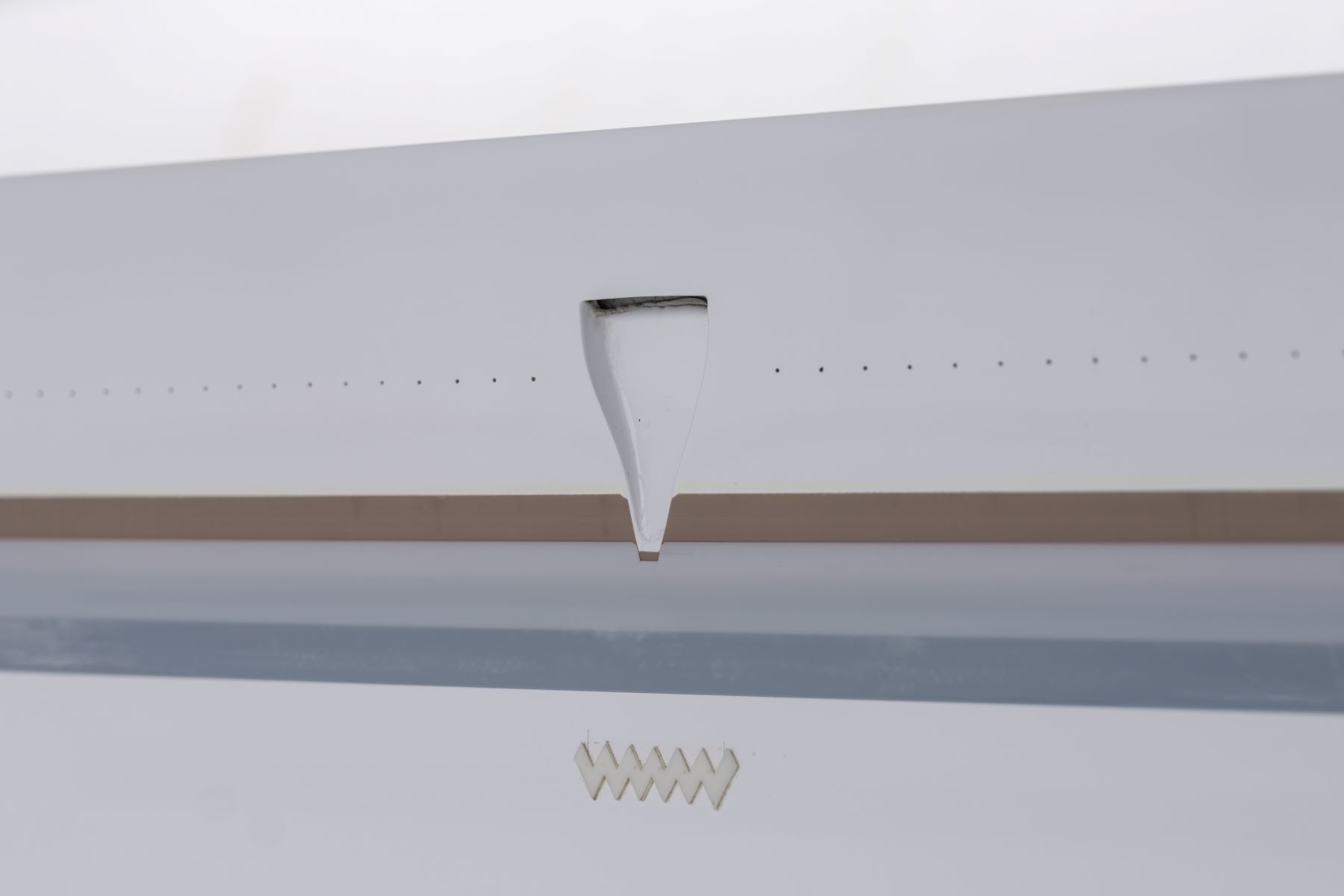

- 6-part wing with boundry layer control on the lower wing surface

- built using high modulous (HM) carbon fibre

- aileron and flap gaps covered with mylartape

- double panel air brakes on the upper wing surface

water ballast

- water ballast bags in inner wings with approx. 48 liter capacity each

- water ballast bags in outer wings with approx. 35 liter capacity each

- water ballast tank in the fin to allow for compensation of CG-movement using water ballast in the wings

finish and design

- white component polyester cout or PU cout

To minimize the structural weight the main parts of wing and fuselage are built using vacuum suction method. This allows the utmost possible spread in wing loading.

Are you curious?

Get to know our aircraft and all their technical features in person – we will be happy to advise you!