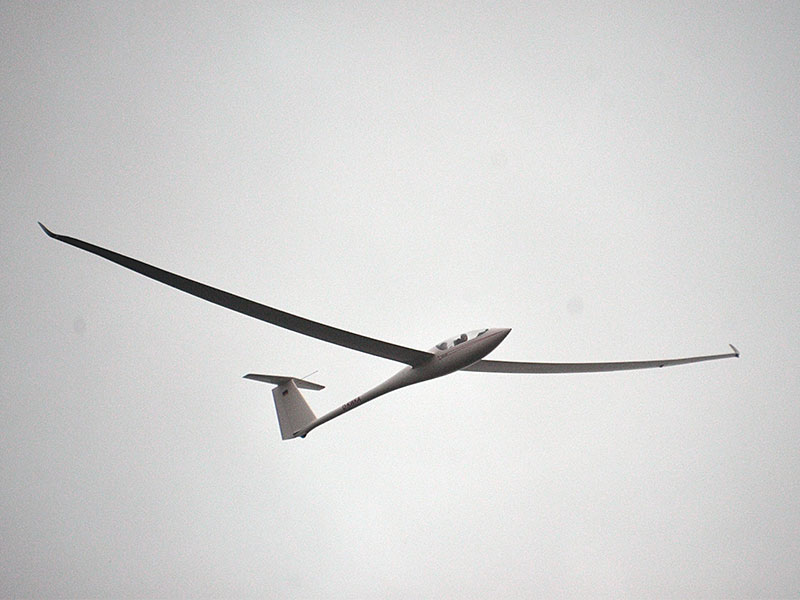

The EB29D combines top performance with comfortable space for two pilots and innovative technology – capable of self-launching, versatile and uncompromisingly safe.

Two-Seater EB29D

Unlimited gliding as a team.

The EB29D offers exceptional flight characteristics, a spacious and ergonomic cabin, and an electric retractable landing gear for maximum comfort – both in flight and on the ground.

Thanks to variable wingspans and low weight, it can be adapted to a wide range of weather conditions and flight requirements at any time.

The EB29D complies with the highest safety standards according to the current CS-22 construction regulations and remains uncompromisingly powerful – for frequent flyers, competitions and leisure pilots alike.

Are you curious?

Get to know our aircraft and all their technical features in person – we will be happy to advise you!

technical data EB29D

| wingspan | 25,3 m | 28,3 m |

| wing area | 15,4 m² | 16,5 m² |

| aspect ratio | 41,6 | 48,5 |

| fuselage length | 8,32 m | 8,32 m |

| height (fin plus tailwheel) | 1,76 m | 1,76 m |

| empty mass with minimum equipment | ca. 570 kg | ca. 580 kg |

| maximum ramp mass | 850 kg | 850 kg |

| wing loading, minimum | ca. 43,8 kg/m² | ca. 41,0 kg/m² |

| wing loading, maximum | 55,2 kg/m² | 51,5 kg/m² |

| maximum speed | 280 km/h | 280 km/h |

| best gliderratio | ca. 63 | ca. 66 |

| Solo engine | ca. 64 hp | ca. 64 hp |

| composite propeller Binder BM-G1 | d 1,6 m | d 1,6 m |

| rate of climb with engine | 2,6 m/s | 2,6 m/s |

| cruise speed in powered flight | max. 160 km/h | max. 160 km/h |

| fuel capacity (standard) | 20 ltr | 20 ltr |

| data sheet | EASA.A.559 | EASA.A.559 |

description EB29D

fuselage

- body shell made of fibre reinforced plastic (CFK and aramide)

- cockpit suitable for pilots up to 190 cm in the front seat and little less in the rear seat

- forward swinging canopy including one sliding window with integrated ventilation scoop

- instrument panel moves upward with the canopy

- TOST-safety release couplings (for aero tow or winch tow)

- total pressure probe in tip of the fuselage nosecone

- adapter in the fin to fit TEK probe

- static pressure probes (for air speed indicator and altimeter) on both sides of the tail boom

landing gear and brake

- rubber suspended, electrically operated retractable landing gear

- hydraulic disk brake

- tail wheel

power plant

- power plant retractable into the fuselage

- solo engine 2625 022

- tooth belt driven reduction gear (1:3)

- water cooling

- double ignition

- electrical starter

- batteries with 16,8 V max charching voltage for improved extension and retraction as well as starting of the engine

- engine control instrument fitted to the instrument panel

- Propeller Binder BM-G1-160-R-120-1

Fuel tank

- In fuselage ~20 ltr

- Flexible fuel tanks in the inner wing with ~17 ltr capacity per wing possible

antenna

- radio antenna in the rudder

- optional transponder antenna

cockpit

- removeable bucket seats with parachute mould in the front seat

- safety belts

- seat cushions

- 2 side Pockets (rear seat)

- ram air entrance in the nosecone of the fuselage for ventilation and defogging of the canopy

- seperately controllable ventilation for both seats on right side of the cockpit

controls

- rudder control pedals on linear rails (adjustable before flight)

- control rods made of CFK

- electrically adjustable trim with operating switches on both control sticks

- automatic elevator connection

wings

- 8-part wing with boundry layer control on the lower wing surface

- wingtip with winglets for wingspan 25,3 m or 28.3 m

- built using high modulous (HM) carbon fibre

- aileron and flap gaps covered with Mylartape

- double panel air brakes on the upper wing surface

water ballast

- water ballast bags in the outer wings with approx. 50 litres capacity each

- water ballast tank in the fin to allow for compensation of CG-movement using water ballast in the wings

finish and design

- white two component plyester coat or PU-coat

To minimize the structural weight the main parts of wing and fuselage are built using the vacuum suction method. This allows the utmost possible spread in wing loading.

Are you curious?

Get to know our aircraft and all their technical features in person – we will be happy to advise you!